Home » Company

IMT - INDUSTRIA MECCANICA TRIVELLE

IMT was founded in 1974 by Mr. Giulio Accorroni, inventor of the first drill rig back in 1958, when water wells were still made using non-industrial methods. This drilling rig was the first rig ever built in Italy, using the driving force of a tractor.

He immediately established the two key factors that, also today, remain the cornerstone for all manufacturing companies in the drilling sector.

With absolute genius, Mr. Accorroni also came up with the idea of the first telescopic kelly bar with interlocking system, and even today, 45 years since his invention in 1973, companies all over the world are still using this brilliant system. This rods locking system during the rotation phase, allows our drills to guarantee that the weight of the entire machine is transferred and applied to the drilling tool during the pushing phase.

In 1980, IMT started to export its drill rigs abroad. From then to now, our reference markets have been mainly North America, (where we have sold over 800 units and are the leader in the field of foundation piles for over 20 years), South East Asia (with about 500 units sold) and over 700 units more sold between the Middle East, Europe and the rest of the world.

In 1993 IMT started collaborating with Caterpillar and, in a few short years, became its main client for special applications mounted on CAT bases.

IMT has mounted over 1,200 rigs mounted on CAT bases, starting from its smallest machines, the AF6, mounted on CAT 211B which reached a depth of 32 m and diameter of 1.2 m, up to its biggest machine, the AF460 drill mounted on CAT 385C which reaches a depth of 110 m and a diameter of 4 m.

COMPANY'S HISTORY

1975

The first innovative hydraulic drill rig (model 75 type G) is patented. Capable of drilling up to a ...

1978

The Accorroni family buys 100% of IMT shares and Giulio Accorroni is appointed IMT’s sole Director...

1984

Fabio Accorroni (Giulio’s first son) dies in an accident and Andrea Accorroni, his younger brother...

1985

The company introduces the 805 model, which soon becomes very successful and used for big constructi...

1992

New innovative models are launched (i.e., sound-proof machine and model AF12, assembled on a crawler...

1993

Beginning of co-operation with Caterpillar (CAT): IMT starts assembling drill rigs on CAT bases (IMT...

1995

Andrea Accorroni takes control of IMT as President and CEO and he's currently running the company

1997

IMT produces the AF50, the biggest drill rig in the world at the time, and sells no. 7 units to the ...

2005

IMT patents an innovative drilling system related to highly seismic grounds, the “Multi Rotary dri...

2010

IMT reacts to the global economic crisis by launching 2 new product lines in the market with traditi...

2011-2013

IMT develops the prototypes for the full range of the AF series drilling rigs with Tier 4 eninges, a...

2015

IMT upgrades the A-series machines with new engines and design, and develops its own particular wate...

2016

The new AF-series machines, mounted on CAT bases with Tier 4 Final engines are developed and lauched...

2017-2019

The brand new range of A-series rigs with new engines of last generation, completely designed and de...

2021-2022

IMT presents the new A70 a compact machine in weight and dimensions but at the same time powerful and performing.

2023

IMT introduces new engines on the white series to be able to operate in low-emission countries in addition to the new A45 and A90.

IMT

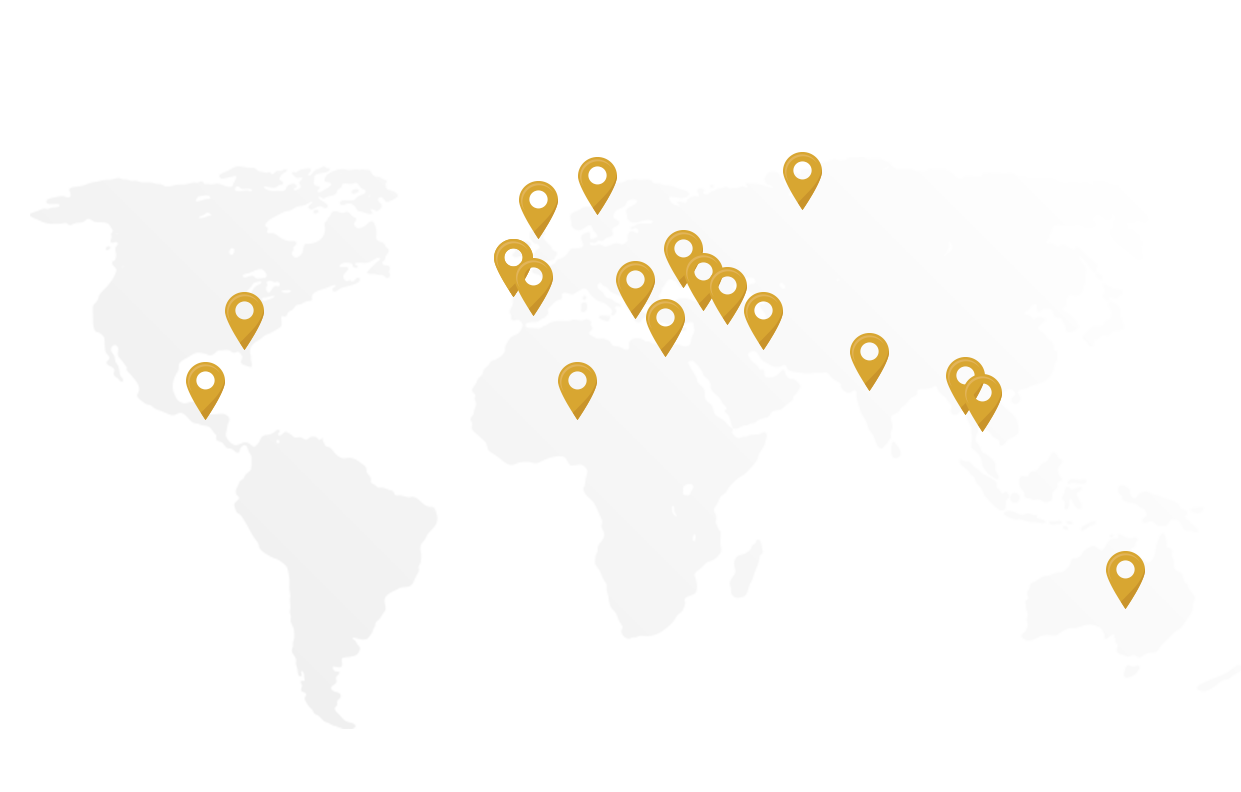

in the World

IMT's staff built supremacy of credibility, excellent quality, service "IMT" brand, and has made outstanding contributions to the development of mechanical manufacturing industry for the whole world. For this you can find a global marketing and post-sales assistance network in over 30 countries in the world.

IMT

in the World

IMT's staff built supremacy of credibility, excellent quality, service "IMT" brand, and has made outstanding contributions to the development of mechanical manufacturing industry for the whole world. For this you can find a global marketing and post-sales assistance network in over 30 countries in the world.